Grande Ronde Hospital

Building a large, cohesive crew of tradespeople from scratch on a remote jobsite was not easy. Operations Manager Mike Reichert, and Superintendents Chris Cory and Andy Brasher worked hard to pull together the successful team. As the largest new construction project to date in the Inland Northwest, there’s a lot to prove in addition to the regular complexities of a healthcare project! From demolition work to gas and water rerouting, underground operations to value engineering, our crews stayed busy alongside necessary subcontractors.

MEP Coordination

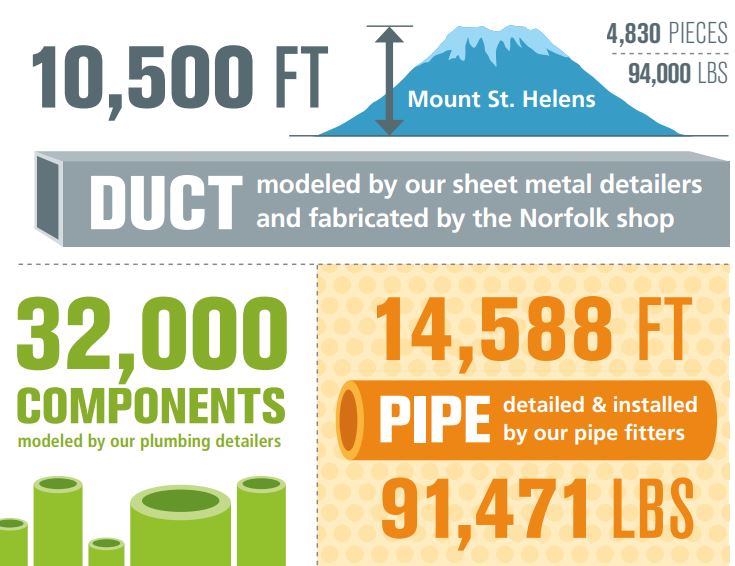

Hospitals themselves are inherently more complicated jobs than others simply due to the number of unique systems in place. In addition to standard plumbing and HVAC, hospitals typically have various medical gas lines/systems, medical vacuum lines and additional mechanical equipment to support key functions/areas of the hospital (and associated piping/ductwork). These additional systems, coupled with the decision by the client to reduce the available ceiling space for all trades for stacked value engineering, made detailing on this job especially important. In many places throughout the building we have mechanical piping, plumbing, medical gas lines, ductwork, as well as electrical and fire protection within mere inches of clearance to structure or other systems. The overhead spaces in the building are extremely congested and the success of making the small available overhead space work would not have been possible without diligent detailing to ensure that all systems fit and function as intended.

Weekly MEP coordination meetings led by the MacMiller detailing team were a huge part of the success of making all systems work in this hospital. Onsite, several data vaults (laptops and screens) provide easy access to BIM files and drawings for the field to continually check accuracy during installation.

The location of the site posed a unique challenge as well, as it is the farthest project from the pre-fabrication shop in Seattle. Delivering prefabricated duct and piping 330 miles to La Grande was a complicated venture due to multiple days of travel and the crossing of two potentially hazardous passes. To overcome this, a shipping hub was established in Kennewick to receive fabricated pieces from both the Portland and Seattle shops. This split the delivery process with items arriving to Kennewick one day, and then being transferred to La Grande the next. The shipping departments, material coordinators, and delivery drivers from Norfolk, Portland, and Kennewick played a crucial role in making this possible. The Grande Ronde Hospital expansion is approximately 75% complete with substantial completion slated for July 2024.

Positive Impact

This hospital expansion in La Grande, Oregon allows the hospital to bring together all surgical services such as patient check-in and pre-op, waiting rooms, operating and procedure rooms, and post-op recovery; as well as space for those departments that support surgical services. The new surgical services space will also provide greater privacy and satisfaction for its patients. This winter the hospital surgeons, nurses and facility team will tour the project before it’s finished with our VR goggles.

Read more from our latest Perspective Newsletter.