Final Install

Final Install

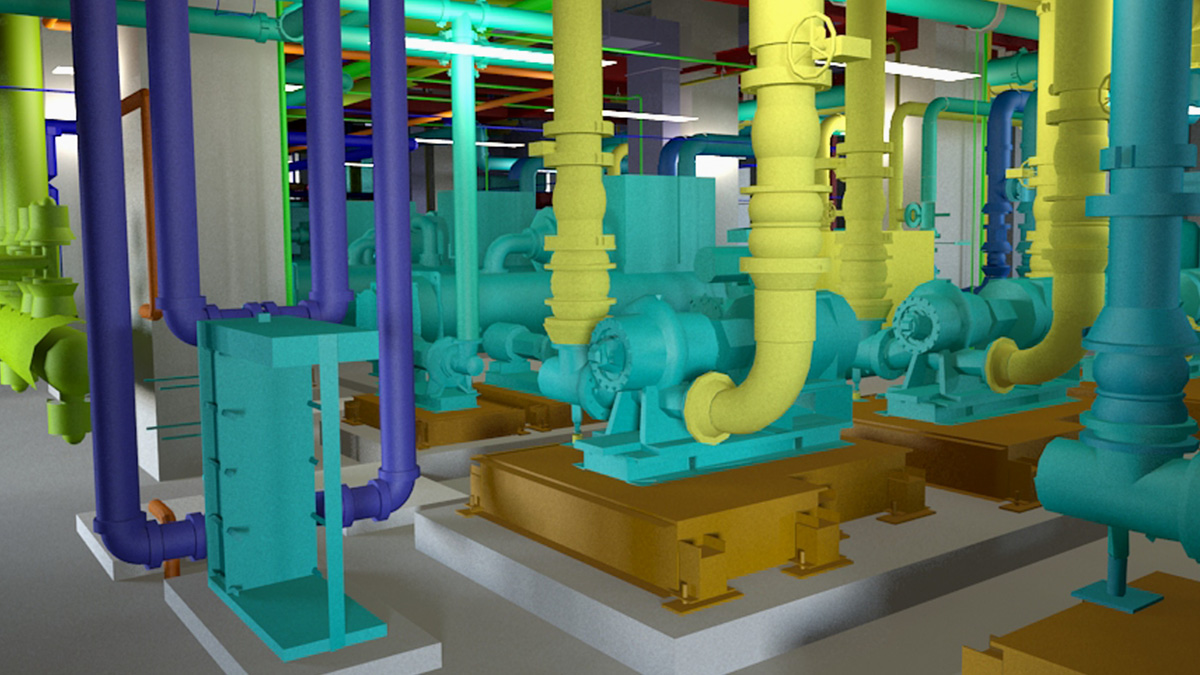

Rendering

Rendering

Our detailing department is one of the largest in the Northwest – and our impressive size is matched only by our impressive expertise. Manned by a skilled team of over 30 full-time detailing craftsmen and an integrated fabrication database, we adeptly handle any project that comes in the door.

Using state-of-the-art technology (including AutoCAD, Revit and NavisWorks), each detailer transforms design drawings into precise 3D models of the project. After this stage MEP Coordination begins, and consistent communication ensures that the systems are installed seamlessly. It’s a process that eliminates confusion and fosters alignment in the field.

As prefabrication becomes the norm, projects require the building information modeling (BIM) and MEP coordination to be increasingly more precise. Thanks to our in-depth resources, we can precisely model systems exactly how they’ll be installed, using virtual parts identical to materials in the field. This allows us to leverage prefabrication opportunities that increase productivity and shorten the project schedule.

Our modeling database is tied into our estimating team and our fabrication software.

This means that once modeling is complete, our estimating team can provide accurate budget information by creating a precise material and labor estimate based on the exact system installation – all at the click of a button. The streamlined processes we’ve developed afford us the ability to quickly send all the drawings and information our shop needs to fabricate ductwork, piping and pre-fabricated racks so they can be installed in the shortest amount of time possible.

Contact Us to learn more

Plumbing Prefabrication

One of the most common and valuable ways we utilize our plumbing prefabrication shop is with prefabricated work packages.

These packages have become standard on all major projects. In detailing, we breakout our piping in to small sections of work and create small batches of piping that can be pre-cut, partially assembled and loaded on to a cart in our shop. Once delivered to site, these packages increase efficiency by allowing our installers to stay within a 12-foot circle of the work and fully complete rough-in in an area before moving to the next package. This is yet another example of how maximum efficiency and high-level quality control have become synonymous with MacDonald-Miller.

Learn more about plumbing prefabricationLet's get started

Would you like a detailed understanding of what MacMiller could do for you?

Contact us today!