Hampton Lumber Mill | Boiler Project

MacDonald-Miller brings our capabilities in boiler efficiencies and energy savings to rural Oregon. Hampton Lumber Mill in Willamina, Oregon is a large producer of dimensional lumber for the building industry, producing 500 million board feet per year, with 40% being kiln dried.

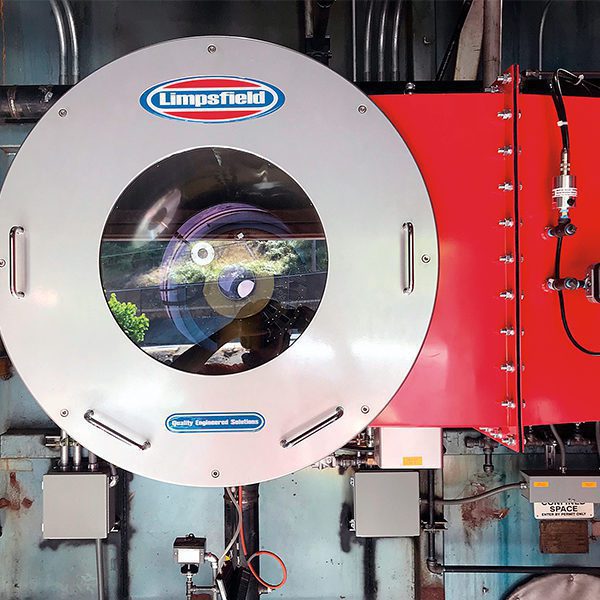

We met the Hampton lumber folks during the WRBA conference in Eugene last year. The team noted that they employed an old Autoflame system on an old Cleaver Brooks burner from the ‘70’s that was highly inefficient. So, we visited the site and shared our solution for updating the controls and providing a new burner.

Consequently, Pete Davila worked with the Oregon Energy Trust to calculate savings that the project would produce – the result allowed for a 70% subsidy of the project by the energy trust! This reduced energy usage came primarily from providing better burner turndown and reducing the need to dump steam in unused kilns. Hampton has run the new system for a couple of kiln runs, and we are seeing better performance without the need to run kilns that aren’t loaded.

We still have some fine tuning to do, but the customer likes the new burner and is very happy with the additional visibility the controls offer. With the DTI (data transfer interface) we were able to virtually place the boiler into the kiln operator’s office for real time views of the burner and firing rates. This was the MacMiller boiler team’s first project in the lumber industry and we’re looking forward to more!

Read our latest Perspective Newsletter